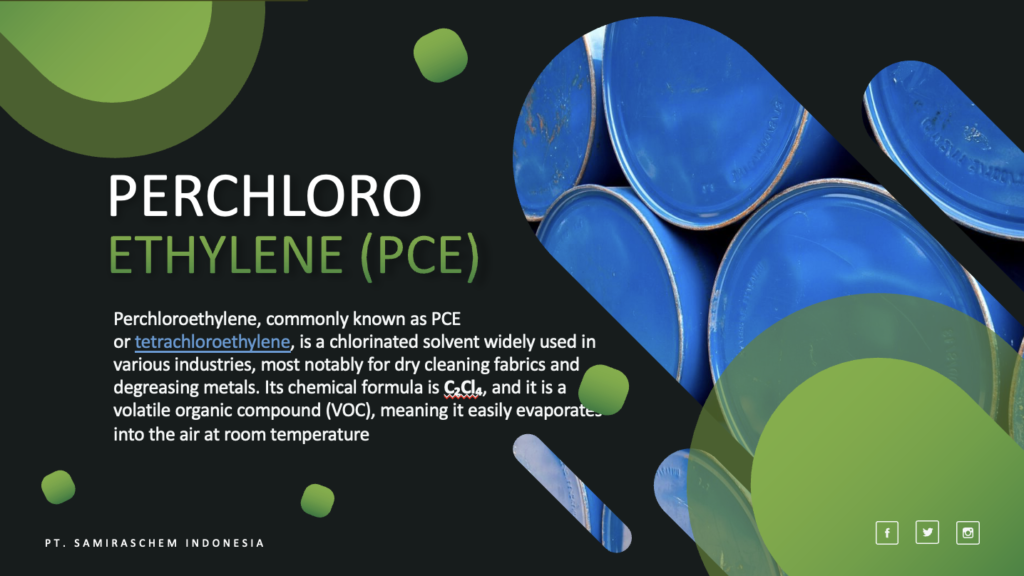

Perchloroethylene

Perchloroethylene, commonly known as PCE or tetrachloroethylene, is a chlorinated solvent widely used in various industries, most notably for dry cleaning fabrics and degreasing metals. Its chemical formula is C₂Cl₄, and it is a volatile organic compound (VOC), meaning it easily evaporates into the air at room temperature. Perchloroethylene is a clear, non-flammable liquid with a mildly sweet, ether-like odor. It has been used for decades due to its excellent cleaning and degreasing properties, but its environmental and health impacts have become a growing concern.

Perchloroethylene: A Comprehensive Overview

In this detailed examination, we will explore the properties, applications, production, environmental and health effects, regulatory measures, and alternatives to perchloroethylene.

Chemical Properties of Perchloroethylene

- Molecular formula: C₂Cl₄

- Molecular weight: 165.83 g/mol

- Appearance: Clear, colorless liquid

- Odor: Sweet, ether-like

- Melting point: -22°C (-7.6°F)

- Boiling point: 121°C (250°F)

- Density: 1.622 g/cm³ at 20°C

- Solubility: Slightly soluble in water (0.015 g/100 mL at 25°C); highly soluble in alcohol, ether, chloroform, and most organic solvents.

- Vapor pressure: 18.5 mmHg at 25°C

These properties make PCE an effective solvent for removing grease, oils, and waxes. Its high density and low vapor pressure make it useful for applications where evaporation needs to be controlled.

Industrial Applications of Perchloroethylene

Perchloroethylene has found extensive use across various industries due to its strong solvent properties. Some of the key applications include:

1. Dry Cleaning

- Primary Use: One of the largest consumers of perchloroethylene is the dry-cleaning industry, where it is commonly referred to as “perc.”

- Role: Perchloroethylene dissolves oils, grease, and waxes from fabrics without causing damage or shrinking, making it an ideal solvent for cleaning delicate fabrics.

- Process: During the dry-cleaning process, clothes are immersed in a cleaning solution containing PCE, which penetrates the fibers to remove soil and stains. The solvent is then recovered, and the garments are dried.

2. Degreasing Metal Components

- Role: Perchloroethylene is widely used in the metalworking industry for degreasing metals, such as engine parts and automotive components.

- Process: Parts are cleaned in vapor degreasing systems where perchloroethylene is heated to its boiling point. The vapor condenses on the cooler surfaces of the metal parts, dissolving oils and grease effectively. The parts are then dried as the solvent evaporates.

- Advantages: The non-flammability and high solvency power of PCE make it an ideal choice for degreasing in settings where safety and efficiency are paramount.

3. Chemical Intermediate

- Role: PCE serves as a precursor in the manufacture of other chemicals, such as hydrofluorocarbons (HFCs) and hydrofluoroolefins (HFOs), which are used as refrigerants.

- Example: PCE can be used to produce trichloroethylene (TCE), another industrial solvent, through various chemical processes.

4. Aerosol Products and Paints

- Role: PCE is also used in aerosol products, adhesives, coatings, and as a solvent in some paints and varnishes.

5. Other Applications

- Textile Industry: Used to clean and finish fabrics.

- Rubber Industry: Utilized for dissolving rubber in certain production processes.

- Automotive: Used in automotive parts cleaning and maintenance.

Production of Perchloroethylene

Perchloroethylene is produced through a process called chlorination of hydrocarbons, usually methane or ethylene. The most common method involves the high-temperature chlorination of hydrocarbons, leading to the substitution of hydrogen atoms with chlorine atoms, resulting in the formation of perchloroethylene. The reaction can be summarized as follows:

C2H4+4Cl2→C2Cl4+4HCl

This process yields perchloroethylene along with other chlorinated hydrocarbons as by-products. These by-products can be separated and purified through distillation and other methods. Large-scale industrial production of PCE began in the early 20th century, driven by its effectiveness as a solvent in dry cleaning and degreasing operations.

Environmental and Health Effects

Despite its wide usage, perchloroethylene poses significant environmental and health risks. These concerns have led to increased regulation and, in some cases, a push to find alternatives.

Environmental Impacts

- Air Pollution

- PCE is classified as a volatile organic compound (VOC), meaning it can easily evaporate into the atmosphere and contribute to air pollution. In areas with significant industrial or dry-cleaning activity, ambient levels of PCE can be elevated, contributing to smog formation and potential long-term environmental degradation.

- Groundwater Contamination

- PCE is highly persistent in soil and water. Once released into the environment, it can migrate into groundwater, where it may remain for extended periods due to its low biodegradability.

- In many instances, PCE contamination has been found in drinking water supplies. Due to its toxicity, long-term exposure through contaminated water sources can have severe health effects on humans and wildlife.

- Ozone Depletion Potential (ODP)

- Although PCE itself has low ozone-depleting potential compared to some chlorinated solvents, its by-products, such as trichloroethylene (TCE) and dichloromethane, may contribute to ozone layer depletion when released into the atmosphere.

Health Effects

PCE is considered hazardous to human health, especially in occupational settings or when used in enclosed spaces without proper ventilation.

- Acute Exposure

- Inhalation: Short-term exposure to high concentrations of PCE can cause dizziness, headaches, nausea, and irritation of the eyes, nose, and throat. In severe cases, exposure can lead to central nervous system (CNS) depression, resulting in loss of coordination, confusion, or even unconsciousness.

- Dermal Exposure: Skin contact with PCE can cause irritation, rashes, or dryness, as it strips away oils from the skin.

- Chronic Exposure

- Cancer Risk: Long-term exposure to PCE has been linked to an increased risk of cancer. The U.S. Environmental Protection Agency (EPA) and the International Agency for Research on Cancer (IARC) classify PCE as a likely human carcinogen, with some studies showing an association with cancers of the esophagus, bladder, and other organs.

- Liver and Kidney Damage: Chronic exposure to Perchloroethylene can lead to liver and kidney damage due to the accumulation of the chemical in fatty tissues and its slow metabolism in the body.

- Neurological Effects: Prolonged exposure can cause neurological effects such as memory loss, cognitive impairments, and mood changes. Workers in industries where PCE is used frequently may suffer from long-term cognitive dysfunction.

- Reproductive and Developmental Effects

- Some studies suggest that exposure to high levels of PCE can impact reproductive health, leading to menstrual disorders, miscarriages, or developmental issues in children born to women who were exposed during pregnancy.

Regulations and Restrictions

Due to the environmental and health risks associated with PCE, various regulations have been implemented to control its use, emissions, and disposal.

- U.S. Environmental Protection Agency (EPA)

- The EPA has set strict limits on Perchloroethylene emissions from dry-cleaning facilities and metal degreasing operations. It has also established guidelines for proper disposal and containment to prevent contamination of soil and water.

- The Safe Drinking Water Act (SDWA) limits the concentration of PCE in public water systems to 0.005 mg/L (5 ppb).

- European Union (EU)

- The EU classifies PCE as a “Substance of Very High Concern” (SVHC) under the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) framework. This classification requires strict control over its use and disposal, as well as the implementation of alternatives where feasible.

- Several European countries have begun phasing out the use of PCE in dry cleaning, promoting alternative solvents that pose fewer health and environmental risks.

- Occupational Safety and Health Administration (OSHA)

- OSHA has set permissible exposure limits (PELs) for PCE in workplaces. The PEL for Perchloroethylene is set at 100 parts per million (ppm) as an 8-hour time-weighted average (TWA), and 200 ppm as a short-term exposure limit (STEL).

Alternatives to Perchloroethylene

Due to its toxicity and environmental persistence, the search for safer alternatives to perchloroethylene has intensified in recent years. Several alternative solvents and technologies have been developed to replace PCE in dry cleaning and degreasing applications.

- Hydrocarbon Solvents

- Hydrocarbon solvents, such as DF-2000 and EcoSolv, have gained popularity as alternatives to PCE in dry cleaning. These solvents are less toxic and have lower environmental impacts, but they are flammable, requiring additional safety precautions.

- Liquid Carbon Dioxide (CO₂)

- Liquid CO₂ cleaning systems use pressurized CO₂ to clean garments. This method is highly effective, non-toxic, and environmentally friendly since CO₂ is a naturally occurring gas that does not contribute to smog or ozone depletion. However, the equipment required for CO₂ cleaning is expensive, limiting its widespread adoption.

- Silicone-Based Solvents

- Solvents such as GreenEarth, which is based on decamethylcyclopentasiloxane (D5), are emerging as popular alternatives in the dry-cleaning industry. These silicone-based solvents are non-toxic, non-flammable, and have lower environmental impact, though concerns have been raised about their persistence in the environment.

- Water-Based Cleaning

- Wet cleaning uses water and specialized detergents to clean fabrics traditionally treated with PCE. Advances in wet cleaning technology have made it a viable option for delicate fabrics, reducing the need for harsh solvents.

- Other Alternatives

- Supercritical fluid cleaning, ionic liquids, and bio-based solvents are under investigation as potential replacements for Perchloroethylene in both dry cleaning and industrial applications.

PT. Samiraschem Indonesia is Reliable Supplier and Distributor Perchloroethylene With High Quality Product and Good Price.

Perchloroethylene has long been a key industrial solvent due to its effectiveness in cleaning and degreasing. However, its environmental persistence, potential for groundwater contamination, and health risks, particularly its carcinogenic potential, have raised significant concerns. While it remains widely used in dry cleaning and degreasing, regulatory pressures and the development of safer alternatives are gradually reducing its prevalence. The future of solvent-based cleaning may rely more on innovative, non-toxic, and environmentally sustainable alternatives that maintain the efficacy of PCE without its harmful side effects.